District heating

Wood chips plant: 250 - 15,000 kW

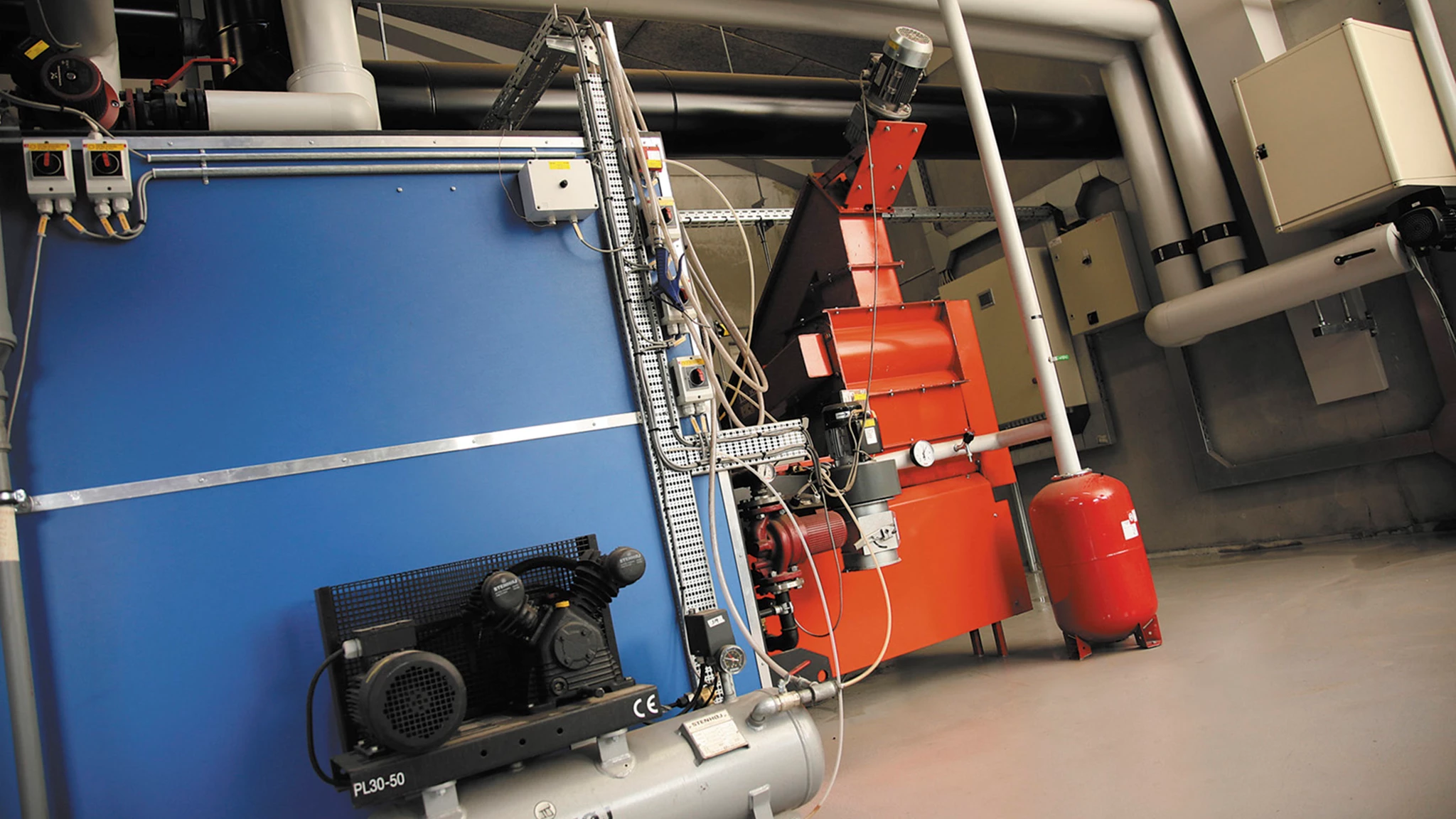

Linka’s fully automated wood chips system consists of a scraper unit, which supplies a constant feed of the pre-set amount of wood chips. The system ensures a complete burnout of the wood chips and efficiencies of up to 96.7 percent.

Hot water plant for wood chips

A biomass plant based on wood chips consists of a walking floor system. A number of horizontal scraper arms moves the wood chips to a sunken auger at the end of the walking floor. This auger is monitored by a photo cell. Whenever the auger is not filled hydraulic cylinders will activate the scraper arms, and continue until the auger is refilled. From here, the wood chips are transported through an inclined auger directly to a cell lock to be fed into the combustion chamber by auger. HEB columns are moulded at the end of the walking floor, and a flat wall is build over the sunken auger.

The auger and the hydraulic cylinder mountings are also moulded. When the boiler “calls” for fuel the feed procedure is activated, i.e. the scraper unit and feeding augers will start.

The scraper unit will now provide the boiler with the appropriate amount of wood chips based on the pre-installed boiler effect. The amount of wood chips is controlled by an oxygen gauge, which constantly monitors the oxygen percentage in the flue gas. . .

Specifications

Linka H-boiler – for wood chips

The H-boiler is a cylindrical, highly efficient channel flue boiler in a 3-pass or 5-pass version, designed for biomass combustion. The boiler features a smooth flame channel and water-cooled rotation chambers. It is dimensioned to achieve full combustion and efficient utilisation of the radiated heat in the flame channel, whilst convection heat is maximum utilised in the subsequent flue gas sections.

A moveable, water- and air cooled step grate is installed in the front of the boiler, to prevent clinker. Through our world patented combustion system, secondary air is added to the process in a downstream principal, to create the correct amount of turbulence in the combustion area. Hereby the developed gasses are completely burned,

resulting in higher efficiencies and better values on emissions. Thorough insulation of the boiler with 100 mm mineral wool results in a minimal heat loss. The boiler is all-welded and gas tight, and delivered with flanges, connecting branches, counter flanges and safety outlets. A cleaning hatch at the backend of the combustion chamber makes inspection and cleaning easy.

The standard version is designed for hot water with an operating pressure of 4 bar, and a maximum operating temperature of 110⁰ C. The H-boiler can be designed for High Pressure Hot Water with a temperature of eg. 160º C, and adjusted for a pressure of eg. 10 bar.

An elegant exterior of blue plastic coated steel plates gives the Linka H-boiler an appealing, modern design.

Automated usability

Linka has many years of experience in developing the special, advanced combustion technology for wood chips and other biofuels, and in utilizing the technology optimally in combustion plants with high operational reliability and usability.

Automatic fuel transport

3-5 hydraulic scrapers are installed in the storage next to the boiler room. The scrapers transport the wood chips to a below-level auger, from which a diagonal auger transports the wood chips to the boiler room.

Automatic ash extraction

A stainless steel, laterally-mounted ash auger is fitted in the base of the boiler, to transport the ash out to the inclined auger. This auger moves the ash onwards to an ash container, e.g. outside the building.

Automatic flue pipe cleaning

A number of pressure tanks are mounted on the boiler along with soot valves. These inject air into the boiler’s flue pipes to keep them clean. This way, manual cleaning of the pipes is rarely necessary.

Electronic control and surveillance system

Control and surveillance of the plant is based on a PLC control system (Programmable Logic Controller). This ensures controlled regulation of fuel supply to maintain maximum heat production from the boiler. All set points are readable and can be adjusted on a touch screen display. The oxygen percentage can also be read simultaneous on the display. Furthermore there is an alarm outlet on the control system.

The control system can also be connected to the internet and accessed by computer, tablet or smartphone. This enables you to receive remote support from Linka during commissioning and maintenance, and in the event of a disruption.

Want to know more about your opportunities?

Our highly qualified team is ready to consult and advice you about the best energy solution based on your specific needs.

Related solutions

Langrigg Hall

Since 2014 Linka has delivered two wood chips plants for Langrigg Hall in Northern England. The newest plant is a 1,500 kW High Pressure Hot Water plant, used for drying wood chips.

Spannarps Manor

The Swedish manor Spannarps uses the heat from a 1,000 kW combined straw and wood chips plant to heat up the poultry shed, in addition to the main building and other properties.

Slättäng Estate

Linka installed a 950 kW combined wood chips and straw plant for Slättäng, which supplies 4,000 m2 of buildings with heat from renewable energy, from their own production.