Combi Boiler for biomass plants

Flexible, sustainable, and environmentally friendly boiler system that optimizes operation with multiple fuel types.

Combi Boiler for all purposes

Linka Energy specializes in the development and production of biomass plants, including combi boilers that can be used for both industrial processes and heating purposes. The combi boiler is characterized by its efficiency, durability, and ability to deliver sustainable energy using renewable, CO2-neutral fuels.

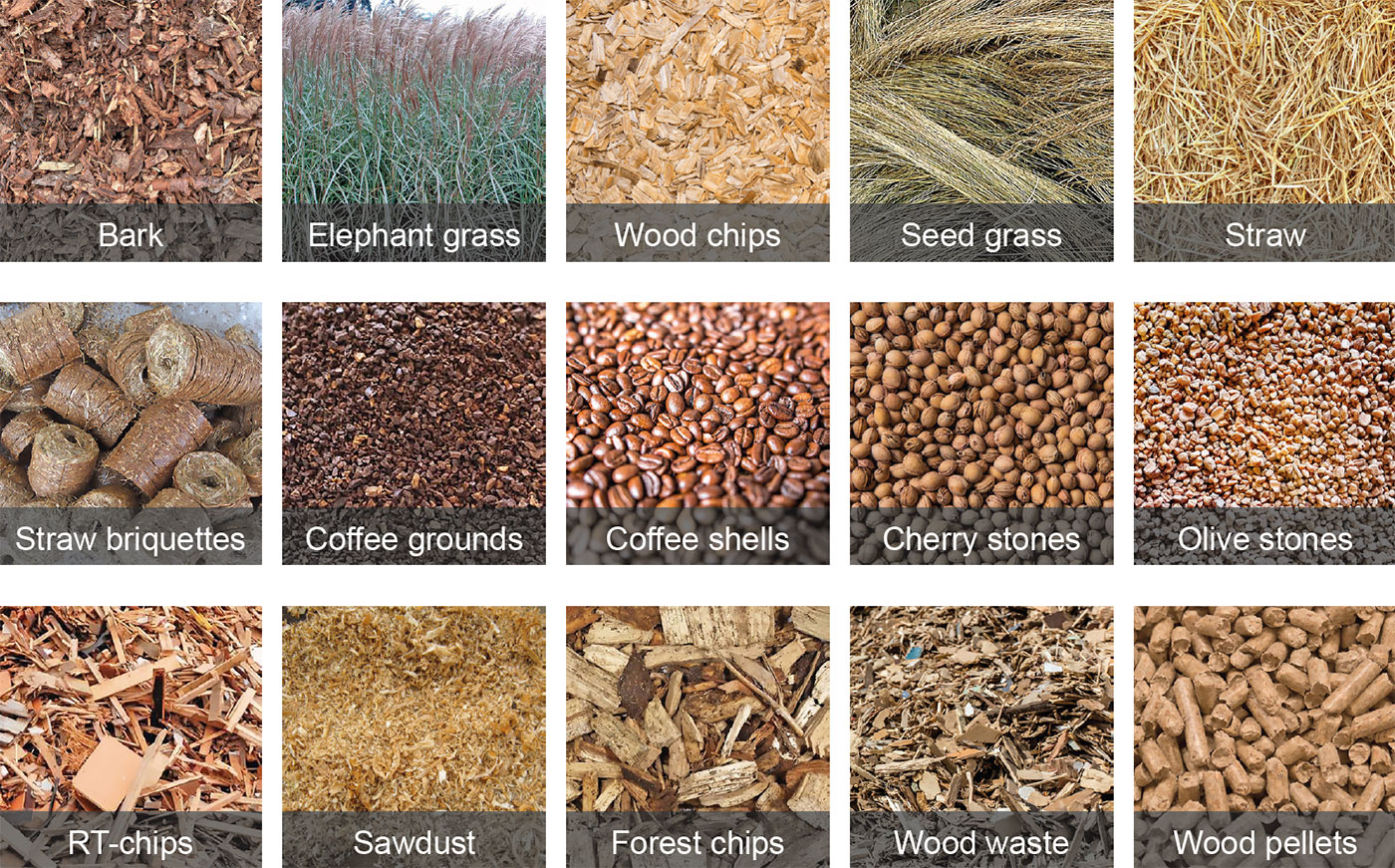

A combi boiler from Linka Energy is a biomass boiler designed to handle various types of fuel, such as wood pellets, wood chips, grain, or other biomass products.

By being able to use different types of fuel, a combi boiler can optimize operation depending on which fuel is most economical or available at a given time. This makes it ideal for both small and large installations where a competitive, flexible, and environmentally friendly solution is needed.

The combi boiler is therefore ideally suited for applications requiring a highly dynamic and adaptable energy solution.

Flexibility vs. specialization

The combi boiler from Linka Energy is designed with several key features that allow the efficient use of different fuel types. Here are some of the most important design features:A mono-fuel boiler is designed for a single type of fuel, whereas the combi boiler can use various types of fuel,

providing greater operational flexibility. This flexibility can lead to economic benefits and makes it easier to adapt to changes in fuel prices and availability. The only thing that matters is that all fuels have a reasonably consistent moisture content.

The primary technological distinction lies in fuel adaptability, with the combi boiler incorporating advanced systems for fuel feeding, air supply regulation, and combustion control, allowing it to optimize combustion across multiple fuel types.

The combi boiler from Linka Energy is designed with several key features that allow the efficient use of different fuel types. Here are some of the most important design features:

- Upgrade of the boiler system to 3-pass and 5-pass configurations, resulting in:

- A reduction in flue gas temperature.

- An increase in efficiency.

- Fuel consumption savings.

- Flexible fuel feeding: The combi boiler can be equipped with either a single or dual feeding system capable of handling various types of biomass fuels, such as wood pellets, wood chips, grain, and other biomass products. This system ensures consistent and secure fuel delivery regardless of type.

- Combustion chamber with adjustable air supply: The combustion chamber of the combi boiler is designed with adjustable air supply,which can be tailored to the specific fuel in use. This is crucial for achieving optimal combustion, resulting in high efficiency and low emissions.

- SRO system (Control and monitoring system): The combi boiler is equipped with an advanced control system that monitors and adjusts the boiler’s operation in real-time. The system regulates combustion parameters such as air volume, fuel feeding, and temperature to optimize efficiency and minimize emissions.

This design makes the combi boiler an adaptable and efficient solution for those seeking a sustainable and reliable heat source that can be adapted to various types of biomass fuels.

The Boiler System

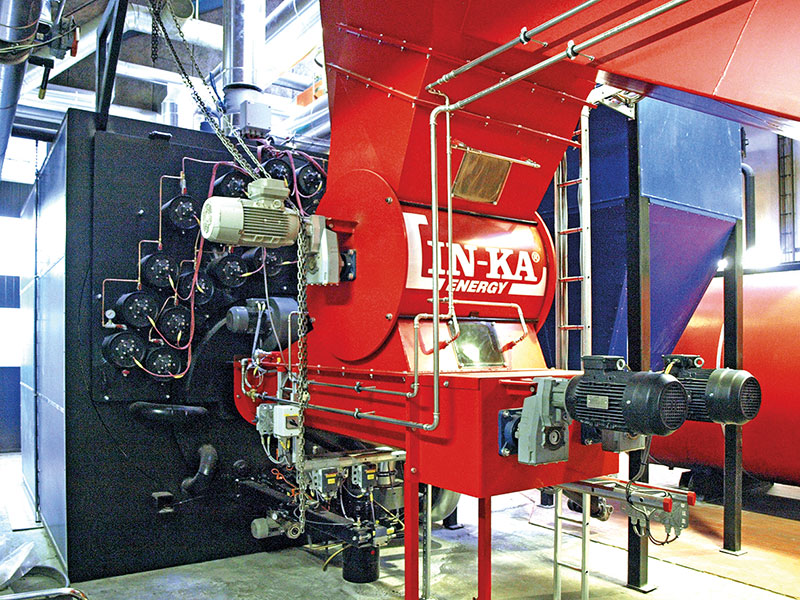

The combi boiler system is based on a Linka® H-boiler with Linka’s patented combustion technology, which ensures maximum fuel utilisation.

It is also equipped with more advanced technology, allowing it to handle multiple types of fuel.

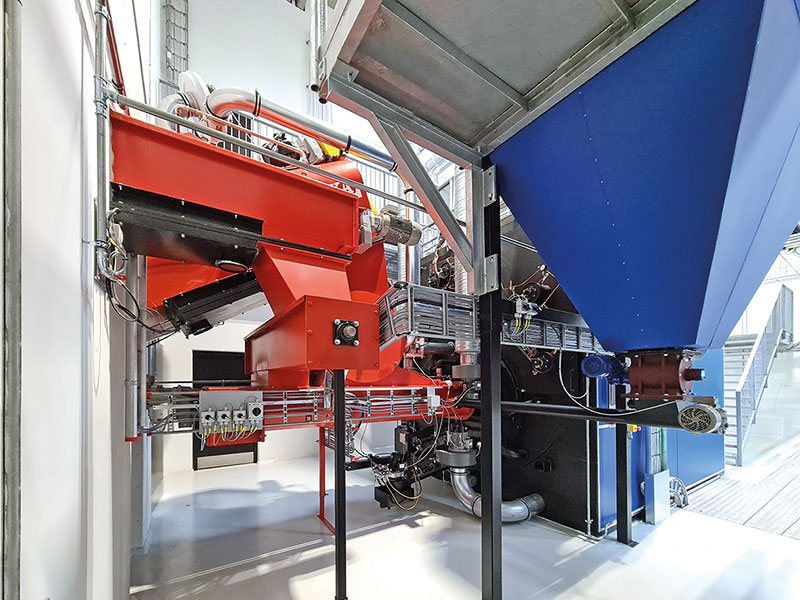

Photos are from Egtved District Heating Plant (left) and Gjerlev District Heating Plant (right).

The plant

The Linkas® combi boiler, supplied as a completely new system, is designed and delivered with two independent feeding systems, such as:

- The straw handling system includes a Linka® straw conveyor and shredder, which adjusts the drum speed according to the boiler’s heat demand. The shredded straw is conveyed to the straw auger, through the cell gate, and into the stoker auger, and is then directed to the moving grate at the front of the boiler.

- The wood chip handling system is supplied with a walking floor system/scraper conveyor, which transports the chips via augers. The scraper conveyor features horizontal frames that direct the fuel to a cross auger monitored by photo sensors. If the auger is not fully loaded, the scraper conveyor is activated automatically. The chips are conveyed through the cell gate to the stoker auger and then to the moving grate in the boiler. The system includes both inclined and cross augers.

The firing process is activated when the system ”calls” for heat, thus initiating the boiler. This triggers the stoker auger of the boiler to start and simultaneously adjusts the speed to ensure accurate dosing for different fuel types. Once the stoker auger is operational, either the straw handling system or the wood chip handling system is activated, and the system will now supply the boiler with the appropriate amount of fuel for the installed boiler capacity.

Flexibility in fuel types

The Linka Combi Boiler offers you more options.