Linka® schredder system - type 100

Efficient and well-proven shredder system for boilers from 800 kW to 1,500 kW

Linka Energy’s shredder system (SINGLE) is a well-proven straw shredder, designed, developed, and produced in the mid-1970s based on the experience Linka has gained through many years of working with biomass. Since then, in 2009, the shredder technology has been refined and developed into the shredder system we have today, which we proudly consider to be one of the best straw shredders in the world.

The power consumption of the straw shredder is the lowest on the market, making it incredibly attractive for energy-conscious district heating plants, industry, and the biogas sector (for straw processing).

The LINKA shredder system can handle various types of straw, including seed grass, rapeseed, wheat, rye, oats, and similar materials.

The shredder system easily processes fuel with up to 25% moisture and can handle both big bales and midi big bales effortlessly.

Thus, the shredder system can be used not only in agriculture, industry, institutions, and heating plants but also in biogas and pyrolysis plants.

Ørnhøj-Grønbjerg KVV

Shredder system for a 1,500 kW straw plant

Mosegården

Shredder system for a 1,000 kW straw plant

Øster Hurup KVV

Shredder system for a 950 kW straw plant

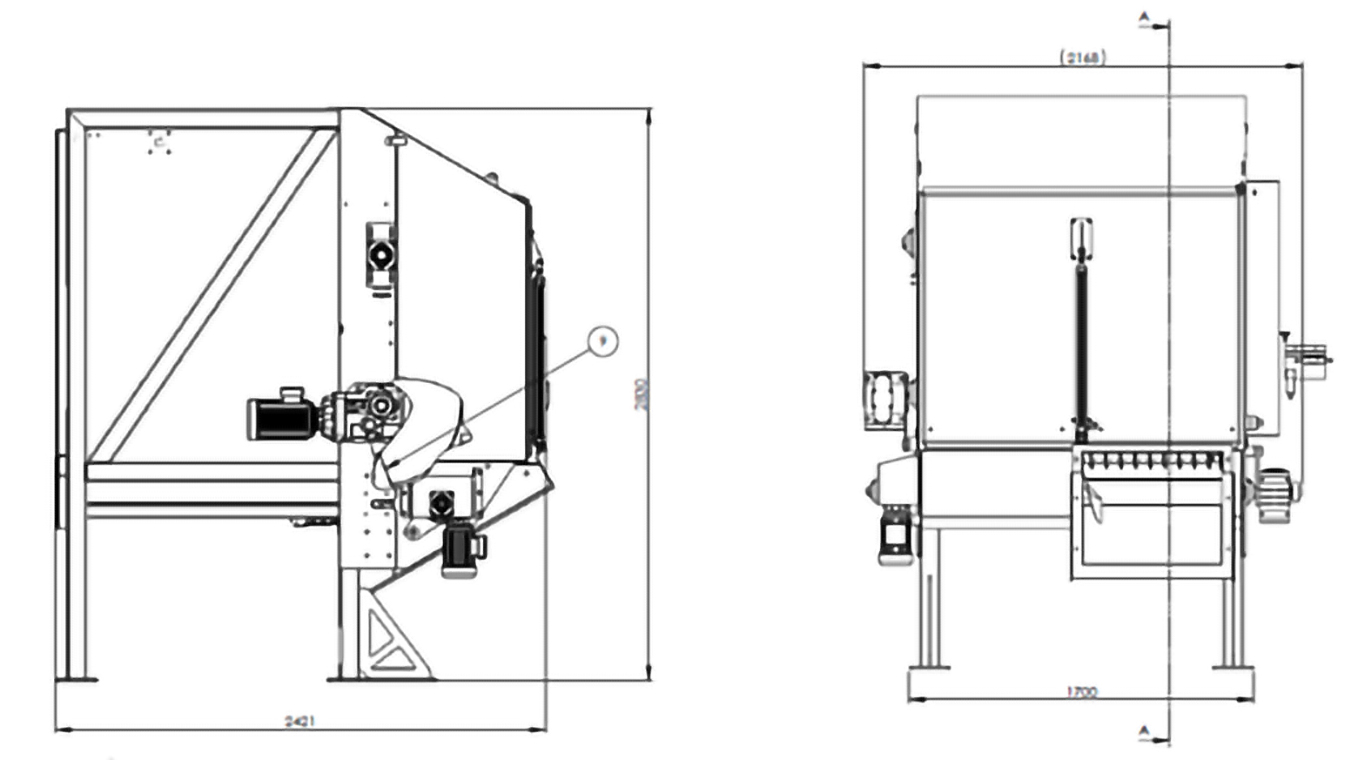

How the Linka® Shredder System works

The Linka® shredder features a drum roller system that operates at low speed, which minimizes the risk of spark formation due to foreign objects in the fuel, as well as wear on the system.

The fuel is pulled upwards, where it is shredded into smaller pieces before falling into the cross auger. The cross auger then transports the shredded fuel to the inclined auger, before the fuel is moved into the stoker and further into the boiler.

The forward movement of the conveyor belt is increased, and the pressure on the shredder drums is adjusted based on amp measurements from the drum, until the desired oxygen level percentage is achieved. Similarly, the speed is reduced if the oxygen level is too low.

The shredder system can be equipped with conveyor belts of a desired length.

Facts

- The straw bales are delivered onto the straw conveyor and transported to the shredder. Here, the drum rollers will shred the straw bale into smaller pieces, which then fall into the cross auger.

- The cross auger transports the shredded straw to the inclined auger, which feeds the straw into the stoker and further into the boiler.

- A safety switch is mounted on the rear doors of the shredder, which stops the machine when the door is opened.

- The shredder is constructed from Steel 37 and has undergone surface treatment.

- The supplied blanking plates/rapeseed sieves should be installed based on consumption and the type of straw.

- The shredder is equipped with an automatic fire extinguishing system that will spray water on the shredder in case of fire. Sensors are installed that fully open at 94ºC, thereby allowing water to flow to the nozzles.

Linka Energy is dedicated to the green transition in both industrial companies and agriculture.

Linka Energy supports the green transition of the industry, promoting sustainable industrialisation worldwide.

Linka helps the energy sector, industry, and agriculture utilise local resources, so together we can create more sustainable cities and communities.

Want to know more about your opportunities?

Our sales department is ready to advise you on your choices, and we would be happy

to provide a non-binding quote for “Linka® shredder system, type 100” for biomass plants, customized to meet your specific requirements.