References

Mørke Fjernvarmeselskab A.m.b.a.

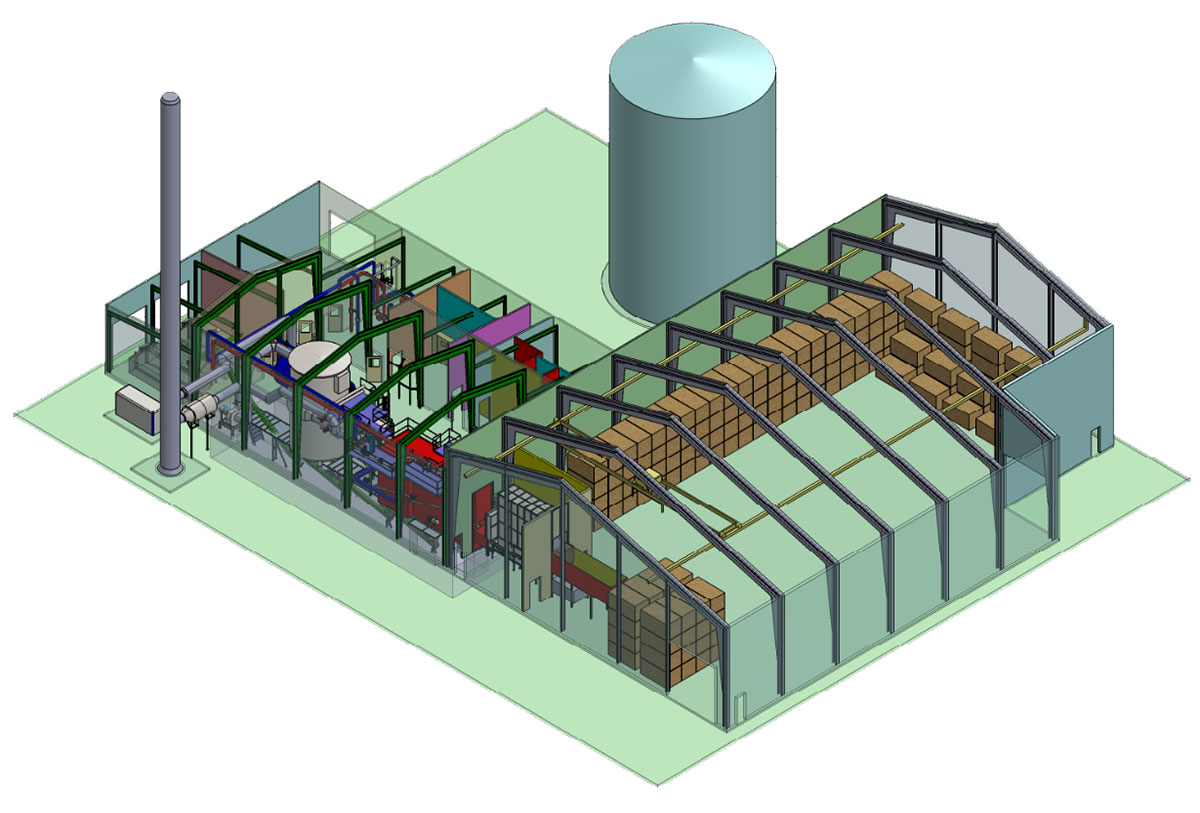

Sustainable upgrade to a complete heating plant with a 4.5 MW straw facility and a 5.0 MW oil boiler backup

The existing heat production – initially a coal boiler, which was converted to wood pellets and subsequently replaced with a Linka H boiler for wood pellets – on Parkvej, built in 1966, faced the challenge of technical wear and tear, technological and energy obsolescence, and had been supplying heat to consumers in Mørke for over 50 years.

Therefore, 2017 became a milestone for Mørke Fjernvarmeselskab A.m.b.a. and its consumers when the new, state-of-the-art straw-fired heating plant on Fabriksvej was constructed.

The investment in a greener future with the new heating plant allows for the complete coverage of heat production using straw – a renewable and local energy source – considering necessary service periods where the new oil boiler, as a backup, ensures a stable and reliable heat supply even during maintenance periods.

The project was tendered on functional requirements and in a turnkey contract covering both buildings and the technical installation, which was won by Linka Energy A/S.

The straw boiler plant

The boiler plant is a 4.5 MW Linka GVB with an economizer, featuring Linka’s patented combustion technology ensuring maximum utilization of the straw.

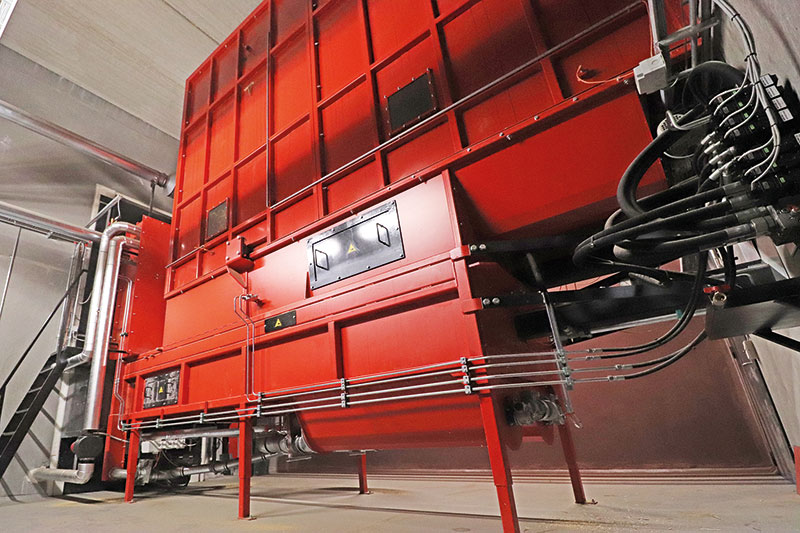

The plant comes with a built-in concrete bridge scale (3×24 meters), which registers the weight of the straw before it is transported to the straw storage. Here, the straw bales are arranged so that the traversing straw crane can effectively sort the rows according to the quality of the straw before delivering them to the LINKA Safety Box. From the safety box, the straw is led through a hydraulic fire door in the firewall into the chopping room. The straw chopper in the chopping room lifts the straw bale into a vertical position, after which a slice of approximately 50 cm is cut from the bale. The slice is slowly pushed into the boiler. The speed at which the straw is pushed onto the combustion grate of the boiler is determined by the oxygen control.

The straw boiler itself is specially designed for biomass, making it more efficient with higher efficiency, and it is designed with a combustion chamber where, in the first smoke passage, connections at different levels can be placed for DeNOx injectors.

The combustion grate is an integral part beneath the boiler construction and is carried on water-cooled bearings with 3 zones, under which grate fall-through, and ash are automatically removed with longitudinal ash augers.

Subsequently, this is led to a water-cooled ash chute, which with a ‘crusher’ destroys any stones and slag formations, allowing it to be further handled in the ash system to the 2 new ash containers.

The flue gas is cleaned in a LINKA Multicyclone and a Teldust bag filter, which reduces dust emissions before being discharged through the 30-meter-high steel chimney. A silencer is installed between the flue gas fan and chimney to future-proof the plant against noise pollution.

The accumulator tank, with a capacity of 1400 m³, is pressure less and equipped with a nitrogen system that delivers nitrogen with purity better than 99.5%, capable of maintaining an overpressure of min. 50 mmWS at the tank top during a discharge of 4.5 MW.

The oil boiler plant

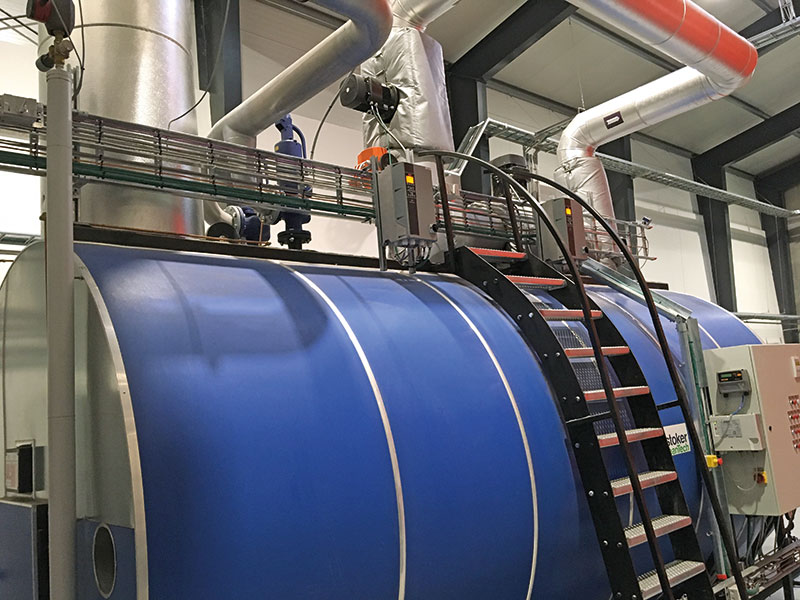

The oil boiler plant serves as a backup for the straw boiler and consists of a 5.0 MW oil boiler, type Danstoker Global 9 LUX.

The oil burner, a Low NOx gas oil burner, type Weishaupt RGL70/2-A, is adapted and installed on the hot water boiler, designed to handle, and maintain an efficient combustion process. For the oil boiler, a double-walled, horizontal 30 m³ oil tank has been provided, equipped with leak monitoring among other features.

At full boiler load, the requirements for NOx and CO are met due to the boiler’s combustion efficiency.

Control of the entire system

The control of the complete system is managed through a comprehensive PLC control system, which monitors the entire installation and sends alarms via internet and SMS. Additionally, it will be possible to monitor the system via smartphones, tablets, and/or PC.

Specifications

Want to know more about this project?

Efficiency, straw boiler

92,3%

Efficiency, oil boiler

90,8%