Linka® electrostatic filter (ESP)

An electrostatic filter with an integrated cleaning system that optimizes the purification of flue gases from biomass boilers.

From January 1, 2025, existing medium-sized biomass plants commissioned before December 20, 2018, and with a nominal thermal input greater than 5 MW must comply with the emission limit values for SO2, NOx, dust, and CO as per as per your national executive order for implementation og the MCP-Directive.

The new requirements will include the installation of a filter system in the form of an electrostatic precipitator (ESP) on all biomass plants.

Linka can assist in understanding the directive and the stricter emission requirements positively to create a better environmental image for biomass firing. Linka offers an electrostatic filter with an integrated cleaning system for purifying flue gases from biomass boilers.

Linka® offers an electrostatic precipitator, also known as an ESP, which removes particles from the flue gas using an electric potential difference.

Facts

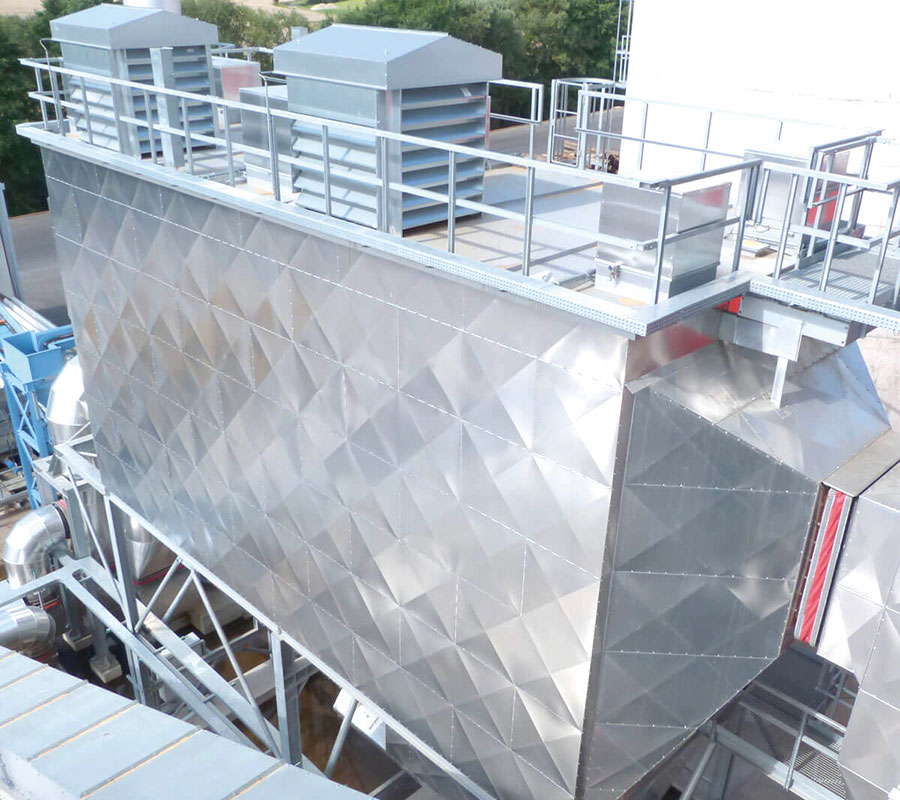

- The filter is delivered as a complete unit, with all wiring, insulation, and cladding done at the factory.

- The filter is equipped with side doors for inspection and service.

- The service area has a handrail installed, and a staircase leading to the ground.

- All exterior surfaces are insulated with mineral wool.

- The cladding is made of aluminium sheets in a colour of the customer’s choice.

- Easy to connect to existing plants that use wood pellets or wood chips. Dust from straw cannot be magnetised.

The energy consumption of the electrostatic precipitator is modest, and it requires only minimal maintenance – as we say at Linka:

Think about the working environment – avoid fly ash in the boiler room.

The technology behind an electrostatic precipitator (ESP)

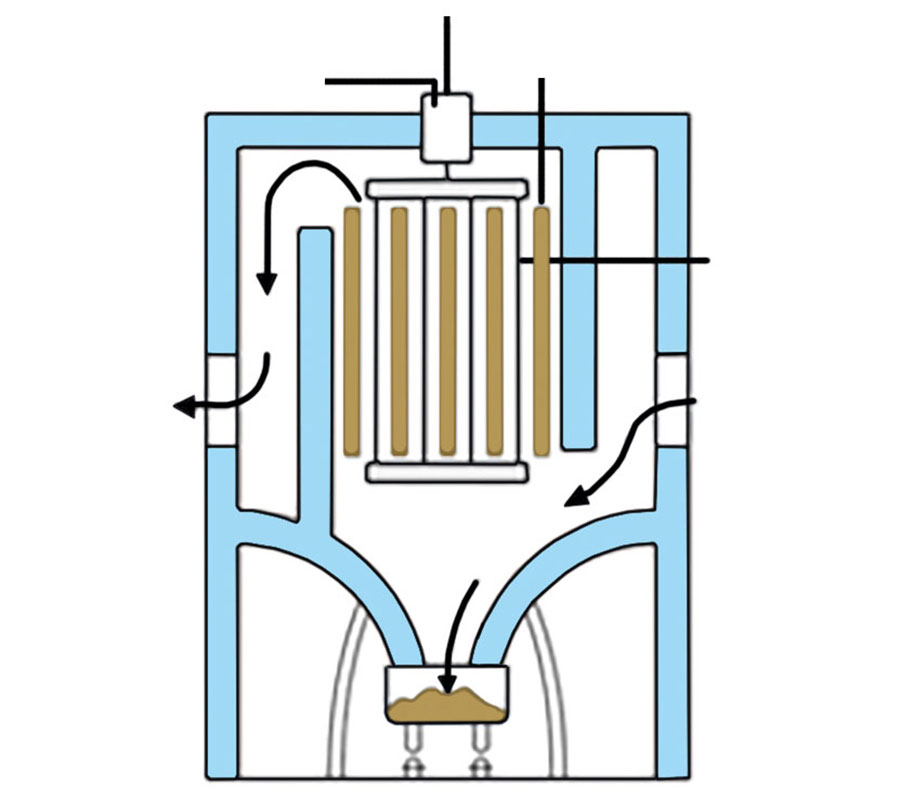

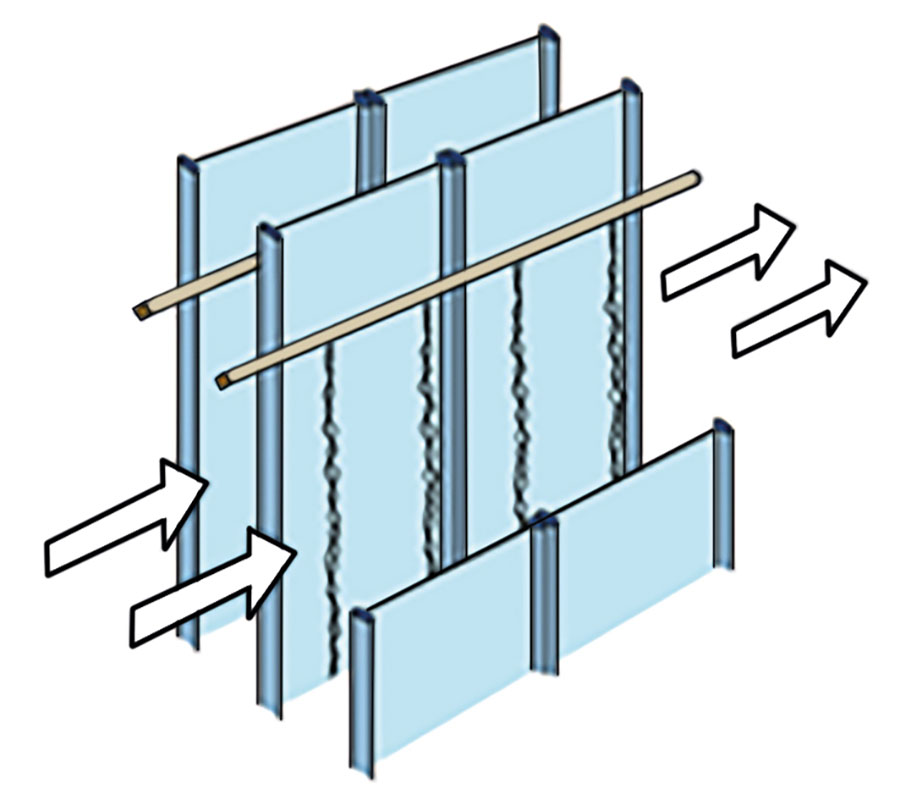

The dust-loaded flue gas is directed through a chamber in the electrostatic precipitator, which is divided into channels by vertical steel plates, also known as precipitation plates. Between the plates, vertical wires are stretched parallel to the plates.

A substantial electric potential difference is applied between the wires and the plates, typically 30-100 kV depending on the distance between them, which gene-rates a weak electric discharge.

This discharge ionizes some of the gas molecules, cau-sing the ions to attach to the dust particles and give them an electric charge. These charged particles are then attracted to the plates, where they are held.

The plates are periodically vibrated, causing the dust to fall into the bottom silo of the filter. From here, dust and ash particles are discharged via an ash auger to the common ash system.

The electrostatic precipitator is one of the most effective methods for removing very fine dust. The increasing requirements for flue gas cleaning have led to higher demand and usage in various processes, including the district heating sector. The energy consumption of the electrostatic precipitator is low, and the maintenance requirement is minimal. The filter is insulated with 100 mm of insulating material and clad with aluminium sheets in a standard colour.

After the flue gas has passed through the filter, the dust emission is reduced to an absolute minimum. The noise emission from the electrostatic precipitator’s “hammers” is less than 70 dB(a) and will be further noise dampened.

After the filter, the flue gas is directed through a frequency-controlled flue gas fan to ensure optimal discharge through the chimney.

Advantages

Linka® recommends an electrostatic precipitator for wood chip/pellet-fired biomass plants because it:

- Cleans automatically and is controlled via a valve control system.

- Is inexpensive to operate.

- Requires minimal supervision.

- Is an investment that can pay off over time.

- Is easy to integrate with an existing plant.

Linka Energy is dedicated to the green transition in both industrial companies and agriculture.

Linka Energy supports the green transition of the industry, promoting sustainable industrialisation worldwide.

Linka helps the energy sector, industry, and agriculture utilise local resources, so together we can create more sustainable cities and communities.