References

Gjerlev Varmeværk A.m.b.a.

Biomass-fired multifuel system with a 2000 kW hot water boiler

Gjerlev Varmeværk A.m.b.a. was established in 1989 and shortly thereafter set up the first straw-fired boiler system – at that time, a preferable alternative to natural gas, which the area was already designated for. In 1990, the new straw plant was inaugurated.

In 2014, the heat plant added a 3,500 m² solar heating system as a supplement to the existing straw-fired boiler system, concurrently with the modernization of the original heat plant.

After careful consideration, in early 2018, Gjerlev Varmeværk A.m.b.a. applied to Randers Municipality for a loan guarantee to establish a new straw and wood chip plant to replace the existing straw plant, which was becoming obsolete.

The combined straw and wood chip boiler system provides the plant with more flexibility to switch between fuels, straw, and wood chips, offering complete freedom in fuel selection – and, not least, carbon-neutral energy and potentially lower heating bills for consumers in the long run.

Linka Energy A/S’ new 2000 kW multifuel biomass system was handed over to Gjerlev Varmeværk A.m.b.a. at the end of 2018.

The plant

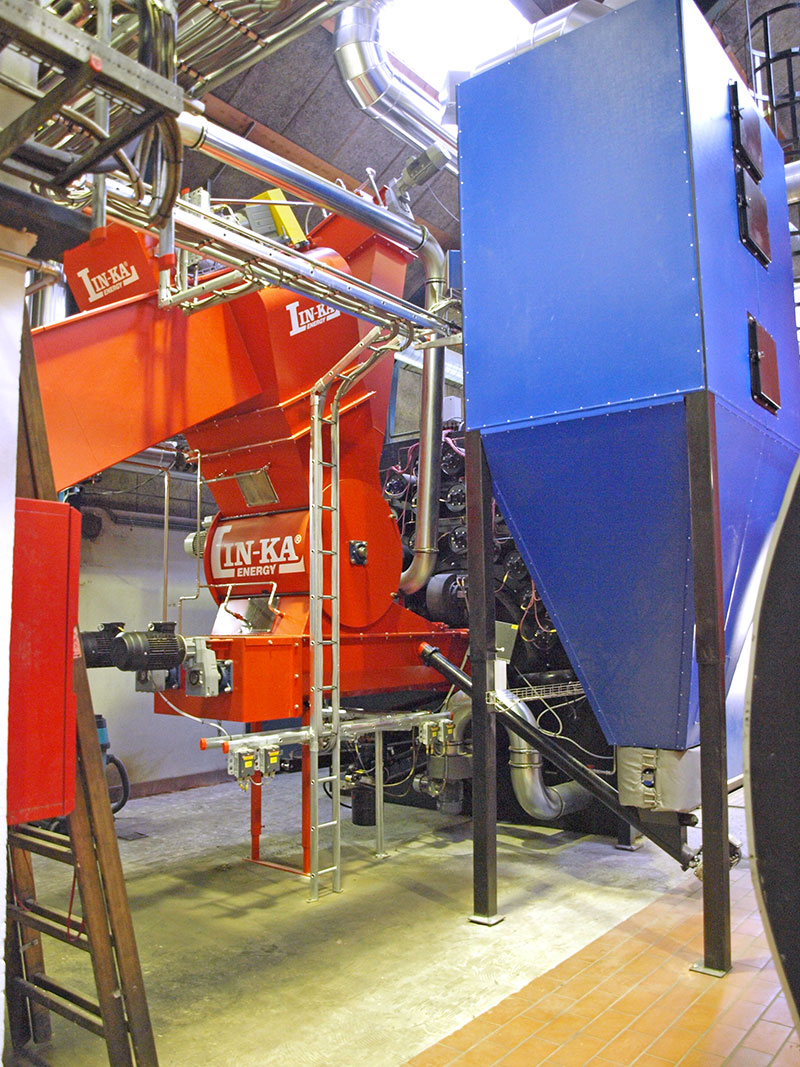

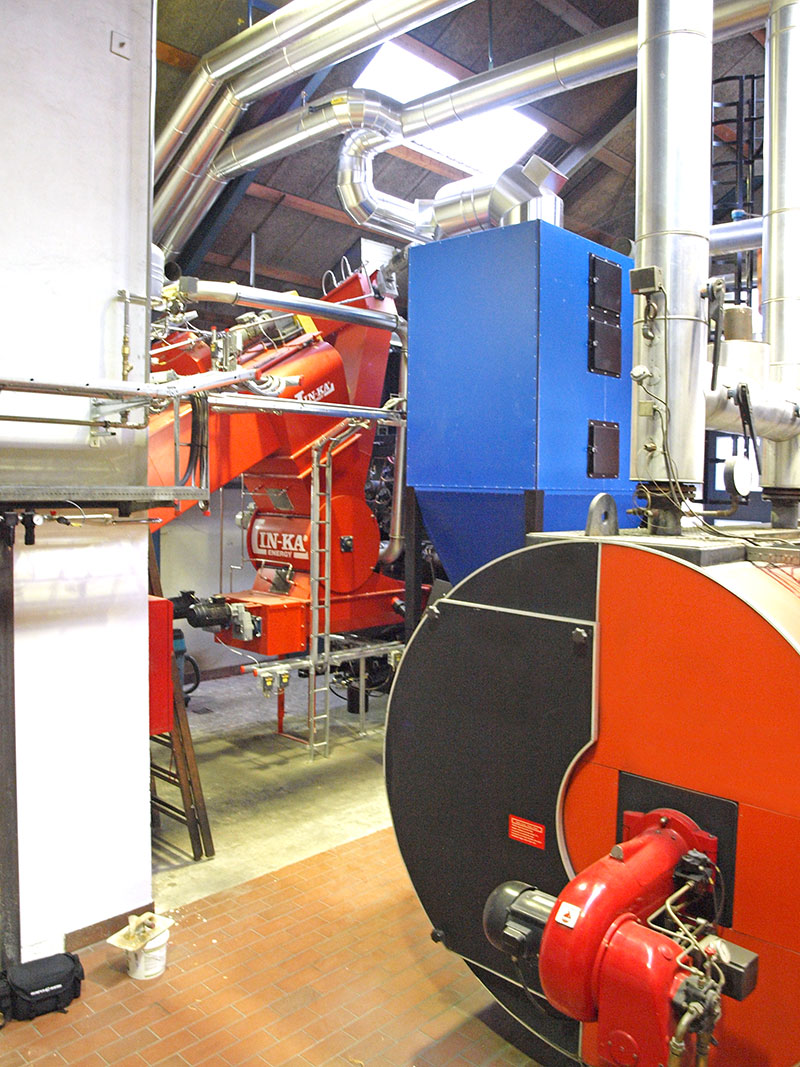

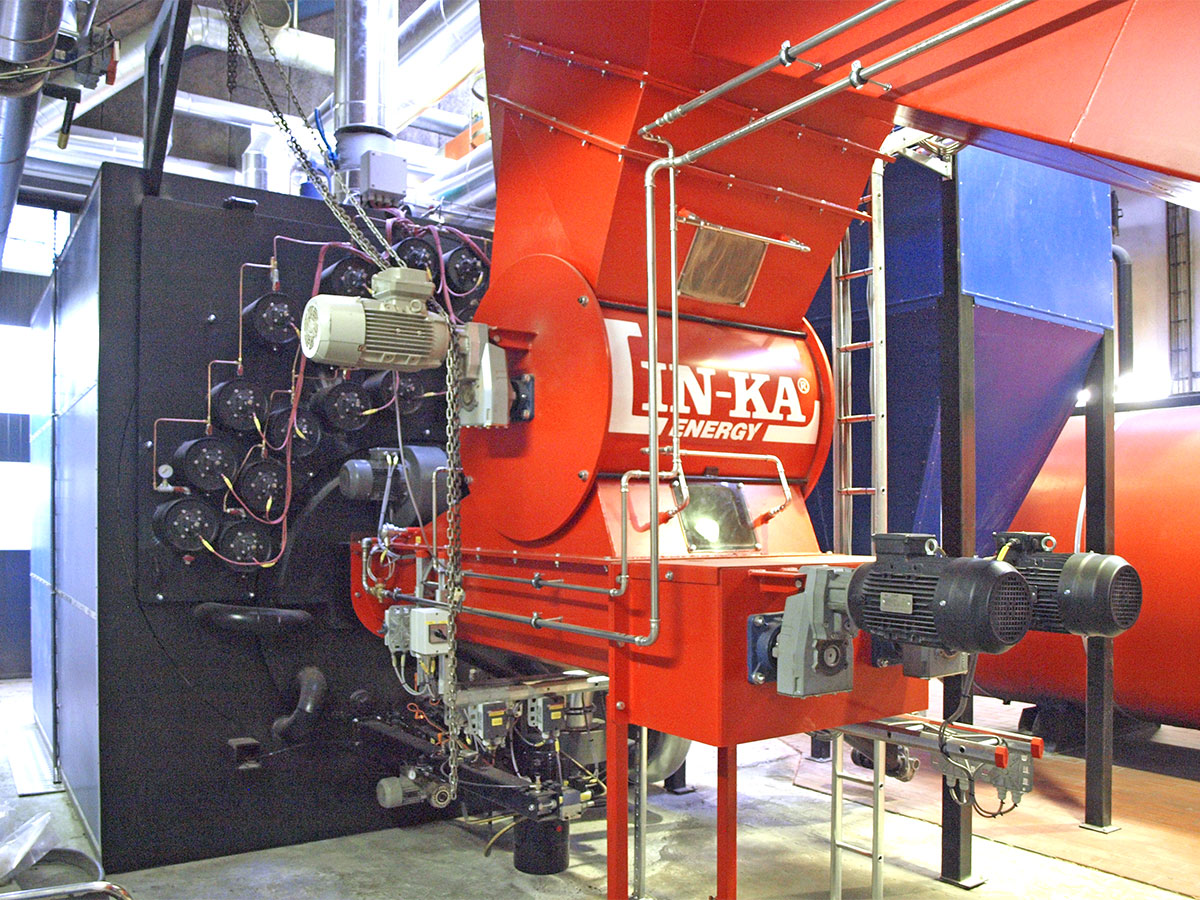

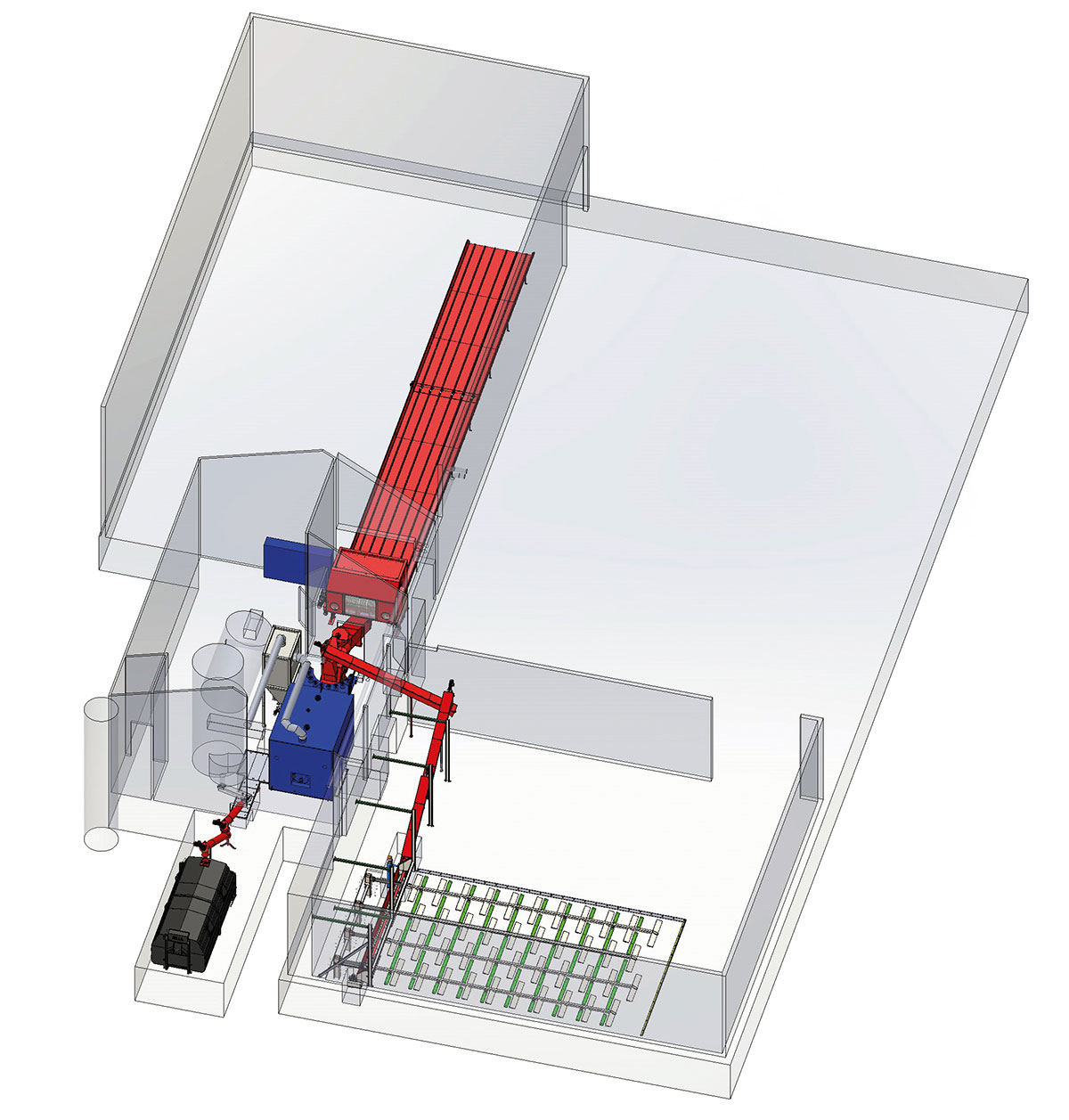

The boiler system consists of a 2000 kW Linka® H 2000 hot water boiler, capable of handling either straw or wood chips. This allows the boiler line with two feeding systems to operate independently of each other, ensuring a high level of security in the heat supply to the process, regardless of whether one of the feeding lines is taken out for service or similar reasons.

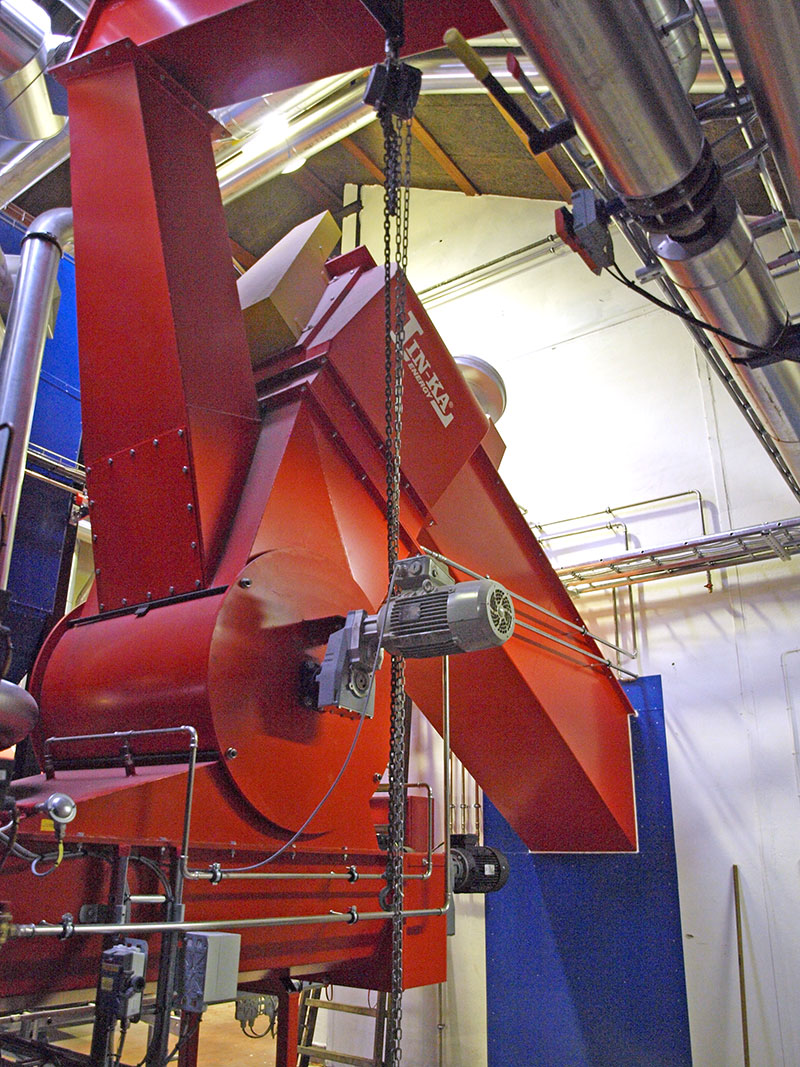

The straw handling system is equipped with a Linka TWIN straw table and a Linka TWIN shredder with rotating drums, controlled based on the boiler’s heat consumption. If the straw production is insufficient, the drum speed is increased. The shredded straw is transported to the straw auger, further to the cell lock and stoker auger (including fire extinguishing system), after which the straw is conveyed to the movable step grate located at the front of the boiler.

The wood chip handling system is delivered with 3 inclined augers and 6 cross augers.

The hot water boiler, type Linka® H 2000, is designed for complete combustion and efficient utilization of radiant heat in the fire channel, while convective heat is maximized in the two subsequent flue gas tube sections. The step grate is constructed to prevent slag formation. Through Linka’s globally patented system, air from the firing end is drawn into the boiler in a counter current principle, efficiently burning the flue gas and yielding improved results in terms of efficiency and emission levels.

For automatic flue gas cleaning, several pressure tanks with shot valves are mounted on the front of the boiler. These valves release air through the boiler’s flue tubes, cleaning them of ash. This results in minimal manual cleaning time for the boiler’s flue tubes.

Additionally, a multicyclone is installed to clean the flue gas, thereby reducing dust emissions through the chimney. The ash is finally transported to a 20m³ ash container.

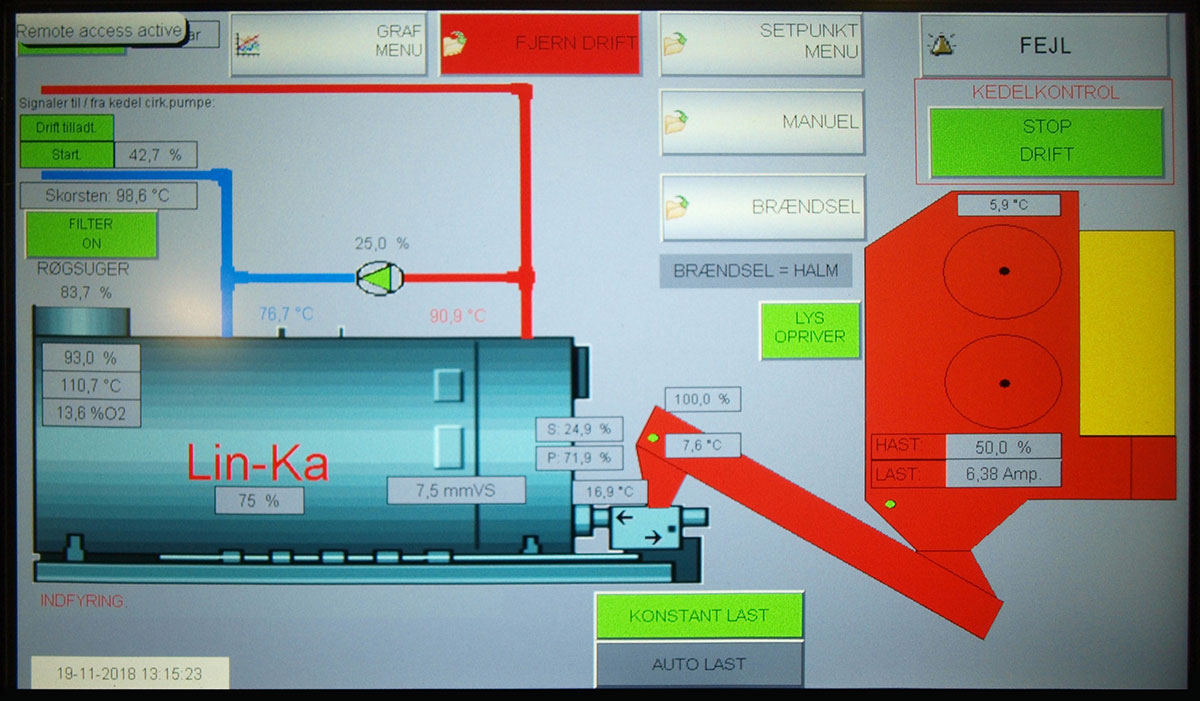

Control of the plant is done with a PLC control system that monitors the plant and sends out alarms via internet and SMS.

Specifications