References

Nimtofte Varmeværk

Sustainable heating plant with a 5 MW straw plant and a 5 MW oil boiler backup

Nimtofte Varmeværk (Nimtofte District Heating), owned by Brdr. Thorsen I/S supplies heat to 405 households.

The heating plant was built during 2007 and was put into operation in the fall of the same year. It is designed to burn biofuels, primarily consisting of straw. Therefore, it is a 100% sustainable heating plant.

Nimtofte Varmeværk (Nimtofte District Heating) provides heat to a network owned by NOFF (Nimtofte og Omegns Fjernvarme Forsyning/District Heating Supply), and the network currently covers Nimtofte town, Lübker Golf Resort, and Ramten town.

The operation of the district heating plant is managed daily by Steffen Thorsen, and Brdr. Thorsen is responsible for supplying straw and labour for the maintenance of the plant.

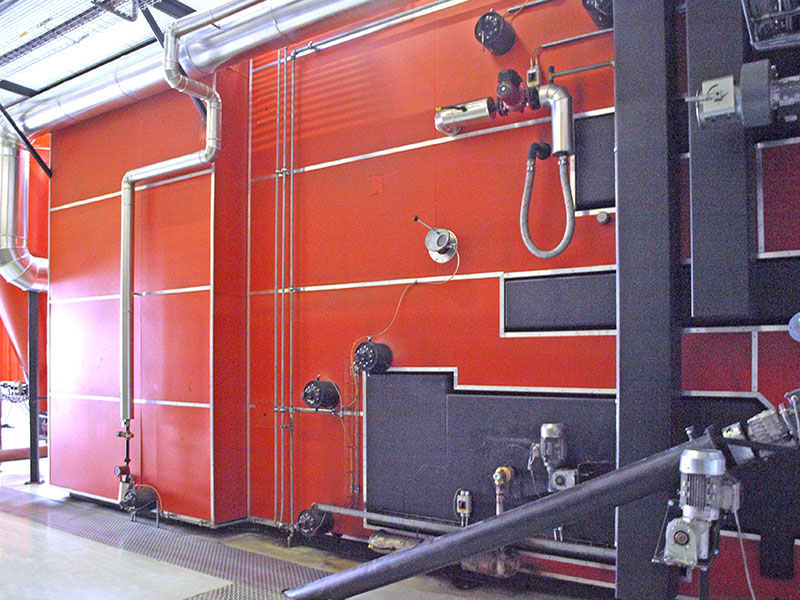

Straw boiler plant

The boiler plant is a 5 MW Linka GVB with an economizer, featuring Linka’s patented combustion technology, en- suring maximum utilization of straw.

The plant is equipped with a 2-rail straw crane for transporting straw bales before they are delivered to a LINKA Safety Box. From the safety box, the straw is conveyed to the straw chopping room.

When the straw bale is fully sliced, a hydraulic straw feed system will transport the straw slice to the boiler door and move onto a set pressure so that the straw is always steady. When the pressure is correct, the boiler door will open, and the firing cylinder will start again. The speed at which the straw is pushed onto the boiler’s combustion grate is determined by the oxygen control.

The boiler will be designed with a square combustion chamber, where nozzles are placed at 3 different levels on the sides. Similarly, nozzles are also placed in the front of the boiler. At the rear of the boiler, a transverse water-cooled tube with nozzles for counter-current combustion is located.

The boiler is configured so that the flue gas temperature at full load is kept at 120°C. To avoid too low flue gas temperature during decreasing load, the boiler is equipped with a damper for bypassing flue gas around the 3rd and 4th flue gas passes.

The flue gas is cleaned in a square LINKA Multicyclone with a cone-shaped bottom, where the smoke is drawn to the top of the cyclone and then forwarded to the bag filter. The ash removal from the boiler consists of an auger, which is placed in a recess under the floor in the boiler room, transversely under the boiler, and is then conveyed from there to the large ash room.

The cleaned flue gas is further released through the 30-meter-high steel chimney.

The 1000 m³ accumulator tank and the nitrogen plant, which supplies nitrogen with a purity of 99.5%, can together maintain a nitrogen pressure of at least 50 mmWS in the tank top under all operating conditions.

Oil boiler system

The oil boiler system serves as a backup for the straw boiler and is a 5 MW oil boiler, Danstoker Global 9 ”Standard” model.

The oil burner, a gas oil burner type Weishaupt RGL70/1-B, is adapted and mounted on the hot water boiler, designed to handle, and maintain an efficient combustion process. For the oil boiler, a double-walled, horizontal 30 m³ oil tank has been supplied, equipped with leakage monitoring, among other features.

Control of the entire system

The control of the entire system is carried out through a comprehensive PLC control system that monitors the entire plant, providing a quick overview of the system’s operation during daily inspections. Additionally, the operator panel will be helpful during service or any necessary repair work.

Specifications