References

Vaarst-Fjellerad Heating Plant

Optimized energy supply for Vaarst

In late 2016 Linka installed a wood chips plant for Vaarst-Fjellerad Heating plant, which is equipped with a crane system enabling automated fuel transport. Before installation of the new biomass plant Vaarst-Fjellerad was one of the 50 most expensive heating plants in Denmark. A settlement behind the Energy Agreement of 2012 enabled these heating plants to switch from gas to biofuel. Vaarst-Fjellerad decided to invest in a biomass plant, making it possible to lower the heating prices considerably in the entire area. Linka was chosen as a turnkey contractor for the solution in Vaarst-Fjellerad, which was erected from scratch. Linka was responsible for designing and dimensioning both the biomass plant and the surrounding buildings. The primary fuel is wet wood chips and Linka needed to design the solution to handle fuel with up to 50 % water.

The plant

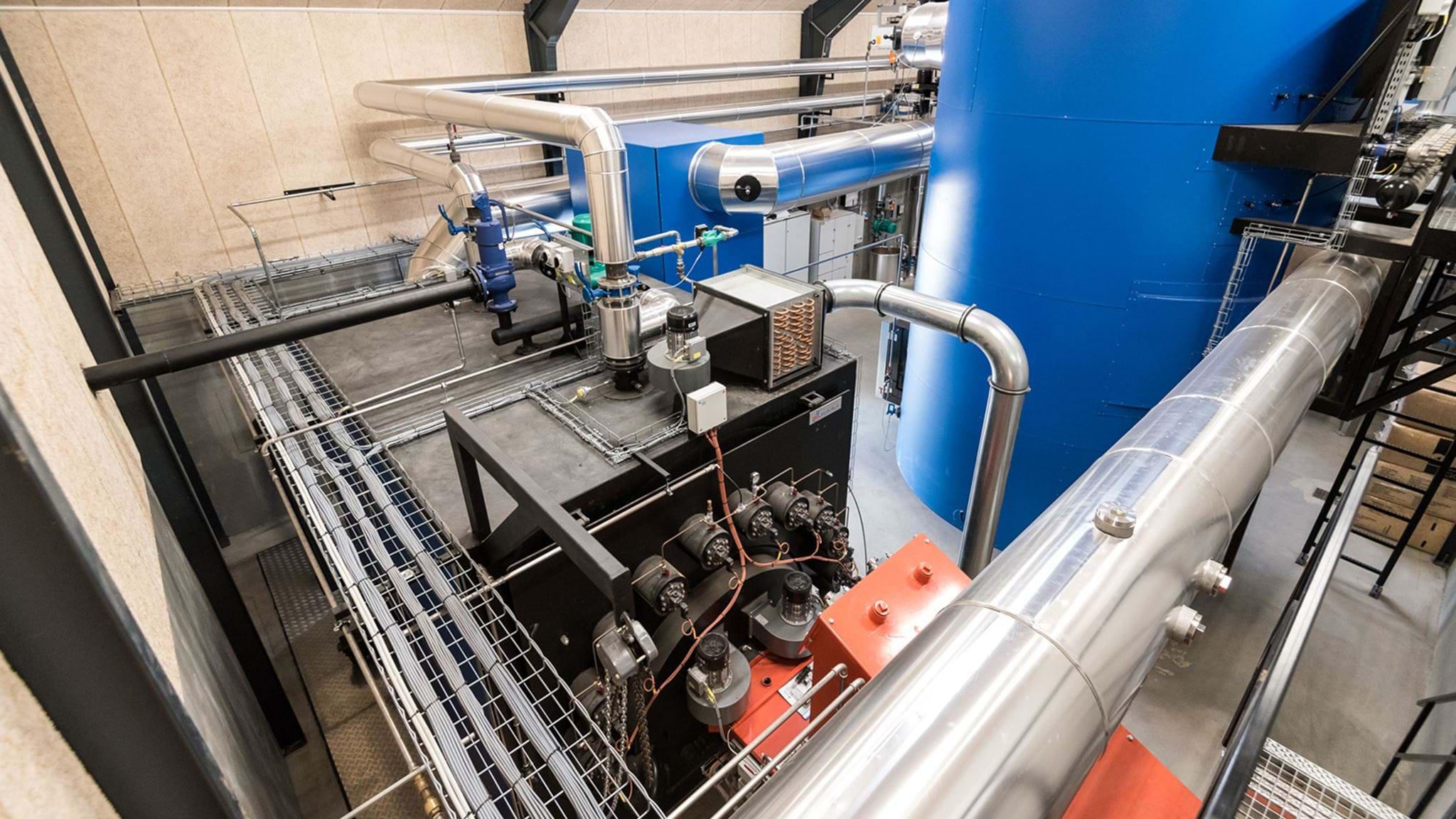

The 1,000 kW wood chips plant installed in Vaarst-Fjellerad, is equipped with automatic fuel supply by crane as well as automatic ash extraction. Thus making it a fully automated plant where photo cells are ensuring a constant supply of wood chips. In addition the ash is transported outside the boiler and into an ash container, located outside the building. By installing a condensing biomass plant the flue gas is condensed and cleaned through a bag filter. This results in more energy and more heat, with less dust. A special feature for this plant is the addition of a filter filled with shavings, which removes cadmium from the condensate by filtering it through the shavings. This is a cost efficient solution which ensures that Vaarst-Fjellerad complies with the emission requirements.

Specifications

Want to know more about this project?

CO koncentration

150

mg/m3

CO emission from the plant is significant-ly below the limit value of 625.

Dust particles

<0,32

mg/m3

The flue gases are cleaned through the bag filter, which reduces dust.