References

MADSEN BIOENERGI I/S

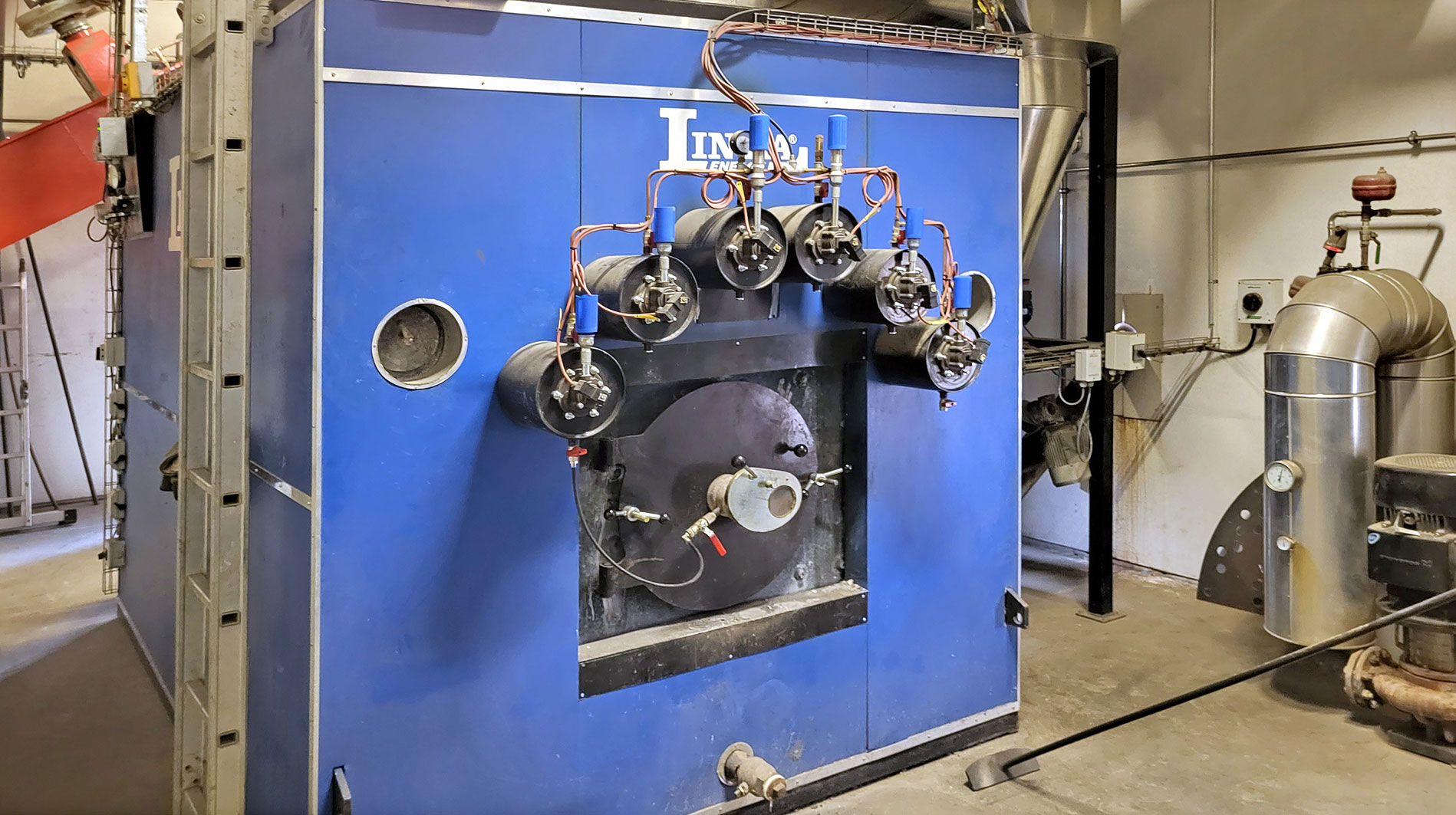

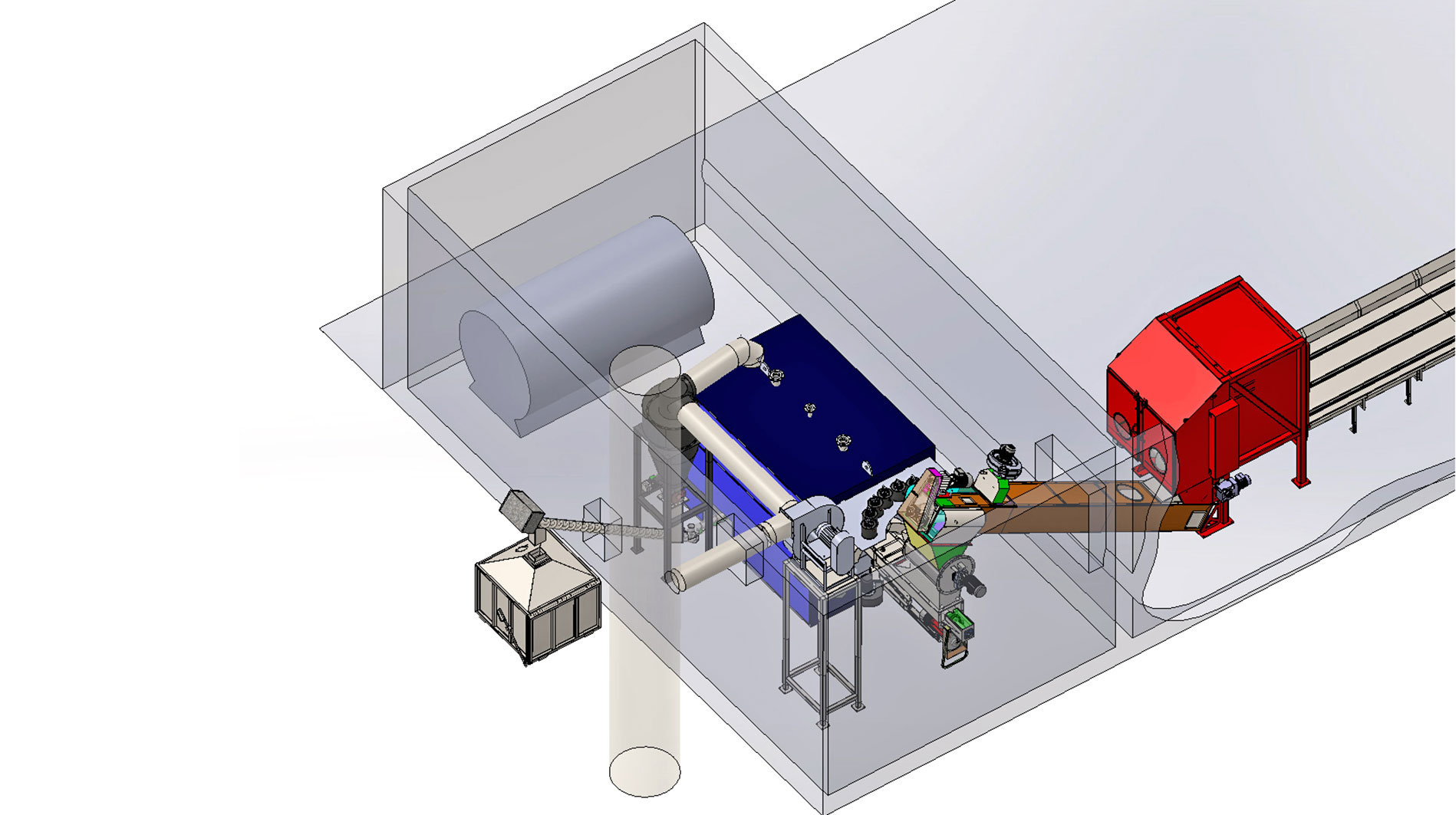

950 kW biomass plant for combined firing with straw and wood chips, as well as an economizer and gas boiler backup

Madsen Bioenergy's biogas plant produces significant amounts of biogas from sources such as deep litter bedding, corn, grass silage, straw, and manure (approximately 170,000 tons per year), supplied by farms within a 10 km radius.

With their focus on green technology, they aimed to convert biogas/methane into natural gas quality.

There's no doubt that all biogas plants are green technologies, and therefore, Madsen Bioenergy chose to collaborate with Linka Energy on the new straw and wood chip combustion plant with a natural gas boiler as backup.

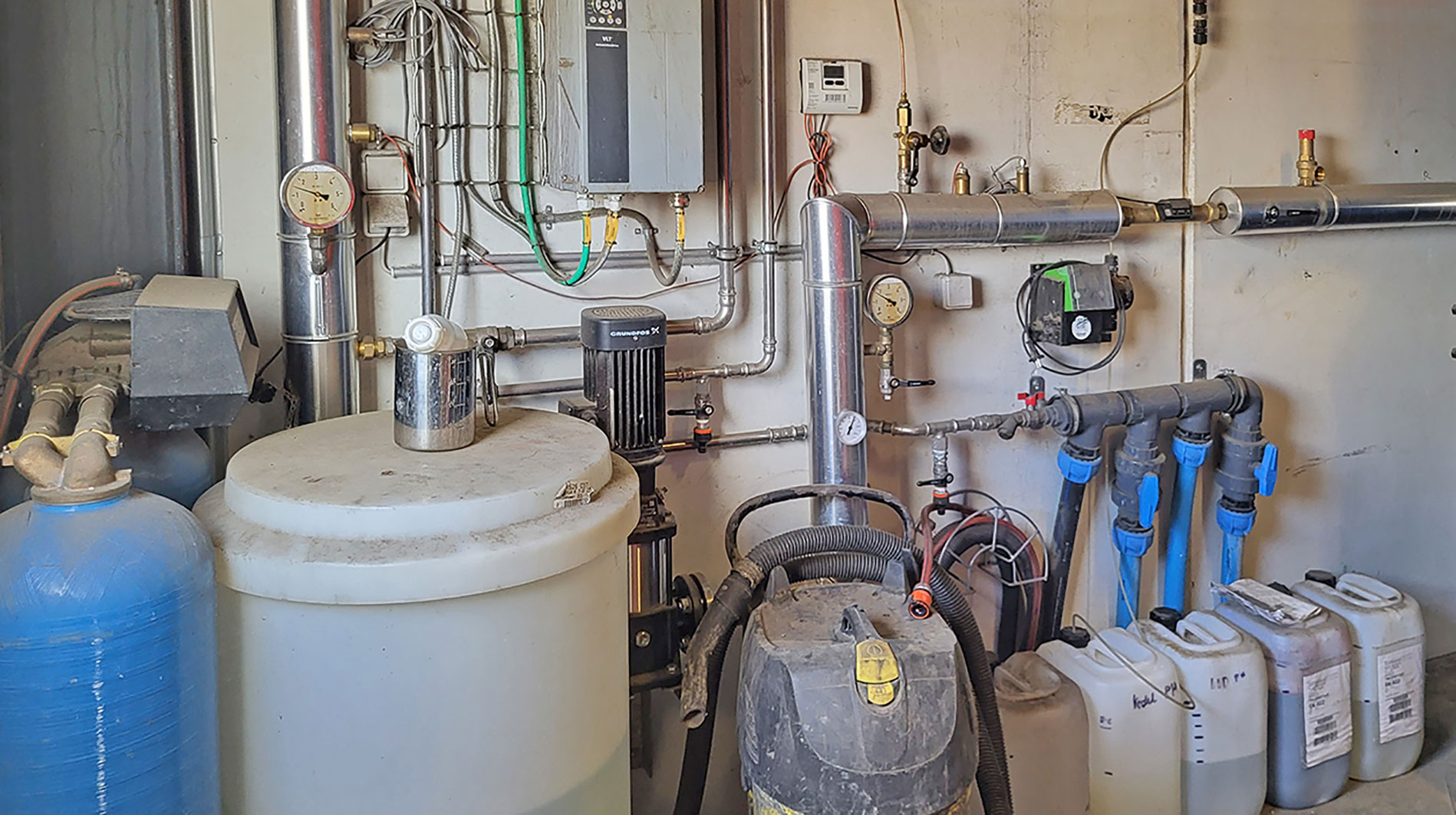

Linka Energy brings many years of experience and know-how in delivering process heat, and in this case, we have worked closely with a partner specialized in biogas handling. Through an absorbent-stripper system with amine purification, the impure gas is upgraded to clean gas before being fed into the natural gas grid.

The upgrade of the biomass plant and the subsequent installation of an economizer, along with the gas boiler, contribute to displacing CO2 emissions. This means that Madsen Bioenergy doesn't add new CO2 to the atmosphere but, in collaboration with Linka, has established what is referred to as a circular cycle.

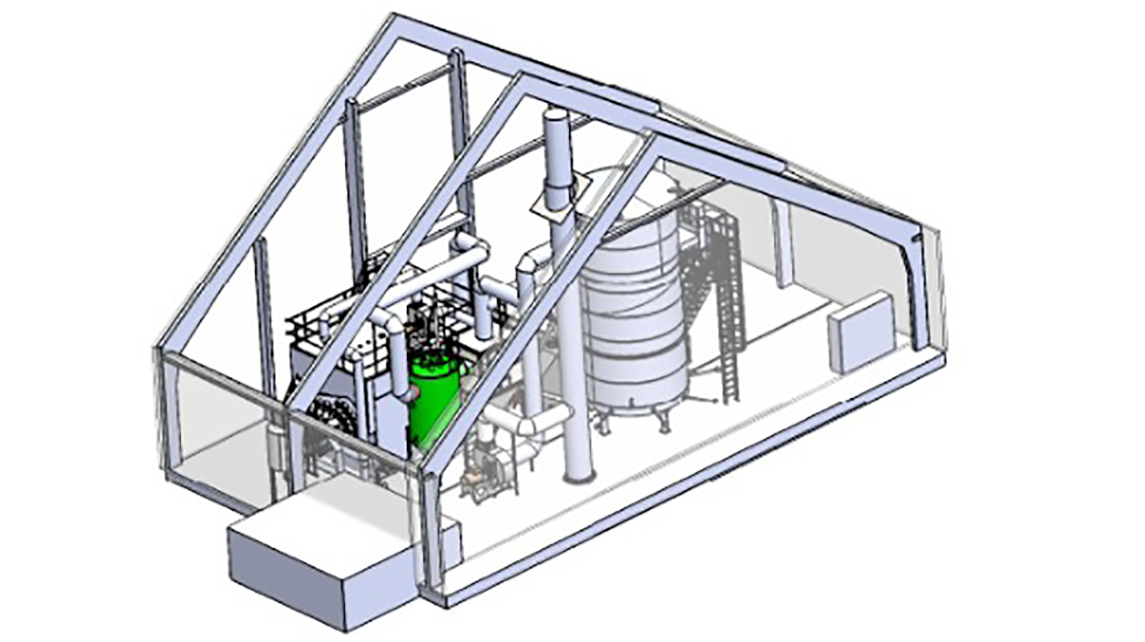

The plant

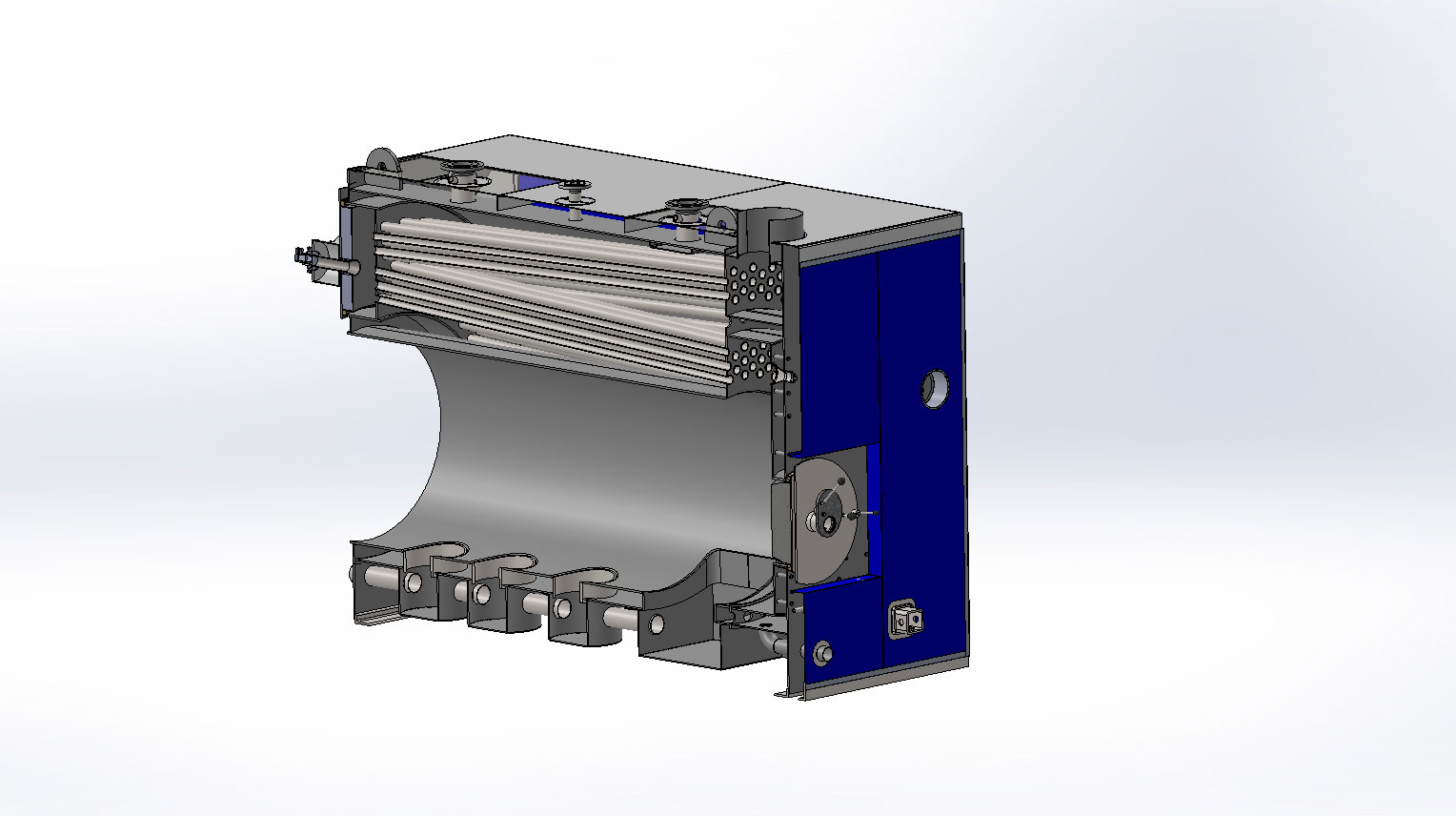

Economizer

In 2020, Madsen Bioenergy additionally installed an economizer with special alloy steel in both flue gas paths. Due to the temperature conditions in the flue gas from the biomass plant, it was possible to extract an additional 100 kW from this setup.

In essence, an economizer functions as a kind of flue gas cooler, transferring energy from the hot flue gas to a cooler medium - in this case, water - which can then be used for preheating or heating. This increases the system's overall efficiency by getting more energy from the same amount of fuel.

An example and prerequisite for this is that the flue gas temperature can be reduced by about 120ºC from 245ºC to 125ºC, resulting in an estimated savings of around 30 kg of straw per produced MW.

For instance, if 8,000 MWh/year is produced, this would translate to an annual savings of 237 tons of straw.

The economizer is connected to the flue gas system immediately after the boiler and before the flue gas cyclone.

Specifications